5 Key Benefits of Polyimide Tape for High-Temperature Applications

<em>"Polyimide tape is the gold standard for thermal management in electronics. Its dielectric strength outperforms most alternatives."</em> – <strong>Dr. Alan Chen, Materials Science Expert</strong>

The Challenge of High-Temperature Adhesive Solutions

Finding a reliable adhesive tape that withstands extreme heat, chemical exposure, and mechanical stress is a major challenge in industries like aerospace, electronics, and automotive. Standard tapes fail under high temperatures, leading to costly downtime and safety risks.

Polyimide tape—a high-performance, heat-resistant adhesive film—offers unmatched durability in demanding environments. This guide explores its benefits, top manufacturers, and real-world applications.

What is Polyimide Tape?

Polyimide tape, also known as Kapton tape, is a thin, flexible film with exceptional thermal stability (up to 500°F/260°C). Its key features include:

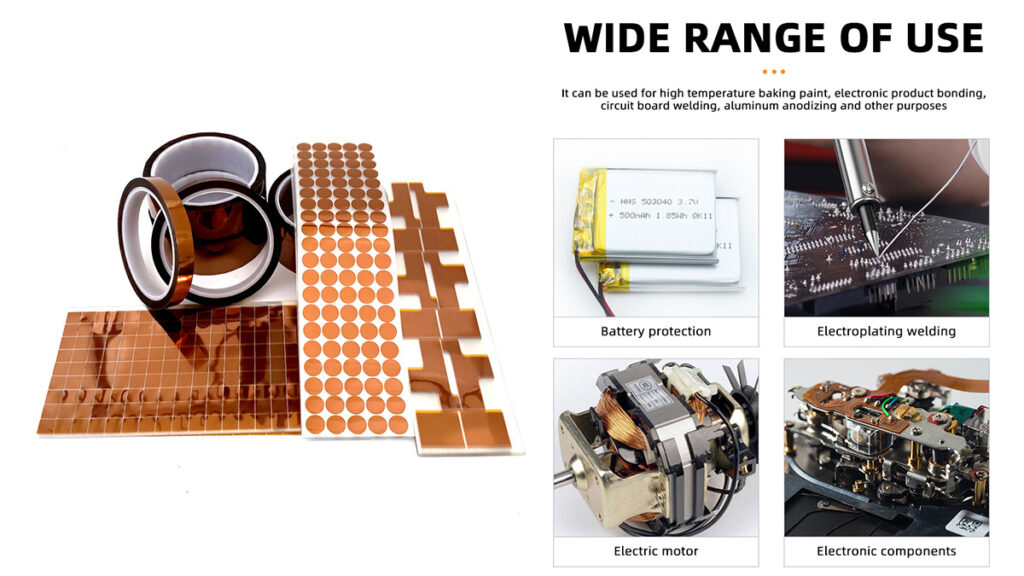

- High-temperature resistance – Ideal for PCB masking, aerospace insulation, and automotive wiring.

- Chemical inertness – Resists solvents, acids, and oils.

- Electrical insulation – Critical for electronics manufacturing.

- Dimensional stability – Minimal shrinkage or expansion under stress.

“Polyimide tape is the gold standard for thermal management in electronics. Its dielectric strength outperforms most alternatives.” – Dr. Alan Chen, Materials Science Expert

Why Choose Polyimide Tape?

1. Unmatched Heat Resistance for Industrial Use

Most adhesive tapes degrade above 300°F (150°C), but [polyimide film tape] maintains integrity up to 500°F (260°C).

Case Study: A leading manufacturer supplied aerospace-grade tape for satellite wiring, reducing heat-related failures by 42% compared to silicone-based alternatives.

2. Superior Electrical Insulation in Electronics

With a dielectric strength of 7,500 V/mil, it prevents short circuits in:

- Flexible printed circuits (FPCs)

- Battery insulation

- Motor and transformer winding

Pro Tip: For SMT (surface-mount technology) applications, use 0.05mm-thick polyimide tape for precision masking.

FAQs:

Q: Is Kapton tape the same as polyimide tape?

✅ Yes, “Kapton” is a brand name (by DuPont) . Other manufacturers produce similar high-performance variants.

Q: Can it be used for thermal insulation?

✅ Absolutely. Its low thermal conductivity (0.12 W/m·K) makes it ideal for heat shielding in engines and electronics.

Q: How does polyimide tape compare to PTFE tape?

✅ While both resist heat, polyimide tape offers better adhesion and flexibility, whereas PTFE tape is more chemically resistant but lacks strong bonding.

Conclusion: Find the Right Solution

Whether you need heat-resistant adhesive tape for industrial or electronic use, it delivers unmatched performance.

Next Steps:

- Request samples for your specific application

Need more insights? Check out our guides on high-temperature adhesives and PCB masking techniques.

Need a tape solution for your project?

Share your application, drawings and target price. Our engineering team will recommend suitable tape structures and send you a quote within 24 hours.

Get a Custom Tape Recommendation