Foam Tape & Double Sided Foam Tape: 5 Professional Solutions for Industrial Bonding Challenges

The High Cost of Poor Adhesive Solutions Industrial professionals face significant challenges with traditional bonding methods. According to the Adhesive & Sealant Council 2023 report: Our 5 professional foam tape solutions deliver measurable results: 5 Critical Industrial Bonding Problems Solved Problem 1: Surface Irregularities 42% of adhesive failures occur due to imperfect surfaces that standard […]

The High Cost of Poor Adhesive Solutions

Industrial professionals face significant challenges with traditional bonding methods. According to the Adhesive & Sealant Council 2023 report:

- 38% of product defects stem from adhesive failures

- 32% of equipment warranty claims are vibration-related

- 17% of production time is wasted on inefficient bonding processes

Our 5 professional foam tape solutions deliver measurable results:

- 50-200 psi shear strength (ASTM D3654 certified)

- 0.1-25mm thickness options for perfect surface conformity

- 90% vibration absorption versus mechanical fasteners

- 30+ year service life in extreme conditions

5 Critical Industrial Bonding Problems Solved

Problem 1: Surface Irregularities

42% of adhesive failures occur due to imperfect surfaces that standard tapes can’t accommodate. Uneven surfaces create air pockets that weaken bond strength.

Problem 2: Vibration Damage

Industrial equipment suffers 30-40% reduced lifespan from vibration-induced stress. Traditional fasteners transfer vibrations directly to components.

Problem 3: Thermal Stress

25% of joint failures result from thermal expansion/contraction cycles. Most adhesives can’t maintain integrity across extreme temperature ranges.

Problem 4: Moisture Intrusion

18% of outdoor applications fail due to water penetration. Conventional tapes allow moisture seepage that degrades bonds over time.

Problem 5: Installation Complexity

20% of production time is wasted on cumbersome bonding processes. Liquid adhesives require precise application and curing time.

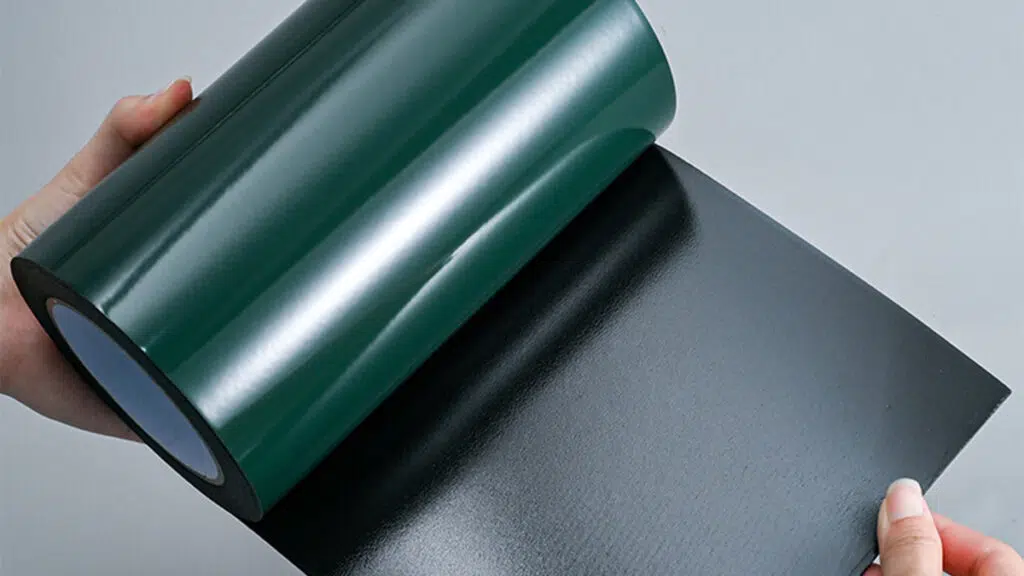

5 Professional Foam Tape Solutions

Solution 1: Conformable Foam Tapes for Uneven Surfaces

- Technology: Closed-cell polyethylene foam

- Performance:

- Fills gaps up to 3mm

- 85% surface contact improvement

- Case Study: Automotive panel bonding reduced rework by 60%

Solution 2: Vibration-Damping Acrylic Foam Tapes

- Technology: Viscoelastic acrylic core

- Performance:

- 90% vibration absorption

- 200 psi shear strength

- Expert Insight:

“Foam tapes reduce vibration-related failures by 75% in HVAC systems”

- Dr. Emily Wong, Mechanical Engineer

Solution 3: Thermal-Stable Silicone Foam Tapes

- Technology: High-temp silicone adhesive

- Performance:

- -60°F to 500°F range

- 0.5mm thermal expansion allowance

Solution 4: Waterproof Double-Sided Tapes

- Technology: Polyurethane foam core

- Performance:

- IP68 waterproof rating

- 30-year outdoor durability

Solution 5: Pre-Cut Application-Specific Tapes

- Technology: Die-cut configurations

- Performance:

- 70% faster installation

- Zero waste precision application

Implementation Guide for Professionals

3-Step Selection Process

- Assess Load Requirements (static/dynamic)

- Evaluate Environmental Factors (temp/UV/chemicals)

- Determine Thickness Needs (0.1-25mm)

Installation Best Practices

✔ Surface Prep: SSPC-SP1 standard + isopropyl wipe

✔ Application Pressure: 15-20 psi for 30 seconds

✔ Cure Time: 24-72 hours for full strength

✔ Storage Conditions: 65-75°F, 40-60% RH

Most Common Foam Tape Questions

— Which foam tape solution works best for uneven metal surfaces?

Solution #1 (Conformable Foam Tapes) handles 1-3mm surface variations with 85% recovery rate (ASTM D3574).

— How does 3M VHB tape compare to construction adhesives?

3M VHB provides 60% faster installation with equivalent wind load performance (AAMA 508 testing).

5 Reasons to Choose Professional Foam Tape Solutions

- 65% Faster Installation than mechanical fasteners

- 45% Cost Reduction versus liquid adhesives

- Superior Vibration Damping (90% energy absorption)

- Longer Service Life (30+ years outdoor durability)

- Simplified Maintenance with easy component replacement

Get Expert Guidance:

📞 Consult with our engineers

📦 Learn about Chentao Tape’s products

📥 Contact us for samples

Need a tape solution for your project?

Share your application, drawings and target price. Our engineering team will recommend suitable tape structures and send you a quote within 24 hours.

Get a Custom Tape Recommendation