Top Die Cutting

Manufacturer from China

ChenTao provides high-quality, durable and reliable industrial tapes.

Aims to provide customers with high-quality tape solutions.

Learn more about ChenTao tapes now!

OUR IMPACT

About Die cutting customization

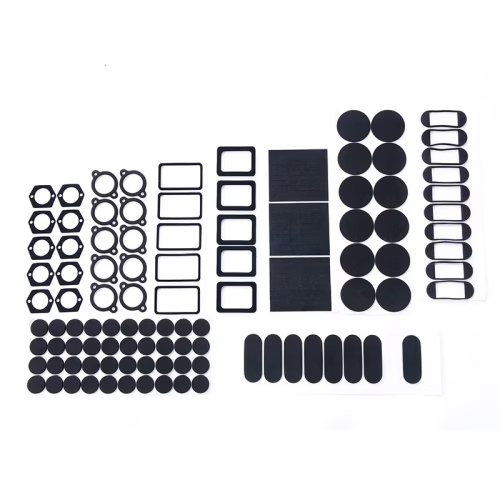

Specializing in precision-engineered solutions, custom die-cutting transforms materials like polymers, metal foils, foams, and adhesive substrates into complex shapes tailored to unique industrial requirements. This process combines advanced die designs with high-accuracy cutting technologies to produce components with tight tolerances, intricate geometries, and consistent repeatability. Ideal for gaskets, seals, EMI shielding, protective pads, or component mounting, it supports rapid prototyping and scalable production across industries such as electronics, automotive, medical devices, and packaging. Custom die-cutting ensures optimal material utilization, cost efficiency, and compliance with specifications for durability, adhesion, or environmental resistance, streamlining integration into end-use applications while minimizing waste.

About Die cutting customization

Specializing in precision-engineered solutions, custom die-cutting transforms materials like polymers, metal foils, foams, and adhesive substrates into complex shapes tailored to unique industrial requirements. This process combines advanced die designs with high-accuracy cutting technologies to produce components with tight tolerances, intricate geometries, and consistent repeatability. Ideal for gaskets, seals, EMI shielding, protective pads, or component mounting, it supports rapid prototyping and scalable production across industries such as electronics, automotive, medical devices, and packaging. Custom die-cutting ensures optimal material utilization, cost efficiency, and compliance with specifications for durability, adhesion, or environmental resistance, streamlining integration into end-use applications while minimizing waste.

ChenTao provides customizable tape solutions

Find the right adhesive tape

In our extensive product line, you'll find tapes for every application

Custom high temperature tape

Custom Insulation Materials

Custom Silicone

Sealing Gaskets

Why choose ChenTao

Expert Adhesive Solutions

We test every product to meet strict quality standards, ensuring strong stickiness and long-lasting performance even in tough conditions.

Fast Custom Orders

Need special sizes or materials? We make samples in 3 days and full orders in 2 weeks – perfect for both small and bulk orders.

Always On Time

98% of orders arrive as promised. Track your production progress online anytime, with quality checks at every step.

Eco-Friendly Production

Our green methods reduce pollution by 68% compared to others. We recycle materials and use safer chemicals.

Global Experience

We’ve shipped to 35+ countries and handle all paperwork. No customs headaches – just smooth deliveries.

24/7 Support

Get instant answers via chat/email/phone. Our engineers help solve application problems, even after purchase.

” As a robotics component supplier in South Korea, we’ve relied on your custom die-cut thermal interface pads for cooling high-density servo motors in our collaborative robots. Over 8 months and 12,000 units, the 0.25mm ±0.02mm precision on graphite-filled silicone sheets reduced motor hotspots from 85°C to 63°C under continuous load, outperforming our previous supplier’s ±0.05mm tolerance pads. The laser kiss-cut backing allowed flawless manual peeling without tearing the fragile composite, and the UL 94 V-0 flame rating passed our mandatory 15-minute burn tests. While material costs were 18% higher initially, your team’s on-site viscosity testing eliminated our secondary adhesive spraying step, cutting assembly time by 40%. We’re now integrating these pads into our semiconductor vacuum robot line exposed to 10⁻⁶ Torr conditions. “